1612 black and white double-headed shift

Share

1612 black and white double-headed shift

Still considering? If you are interested, you canContact us!

Keywords:

- Product Description

-

Product Features

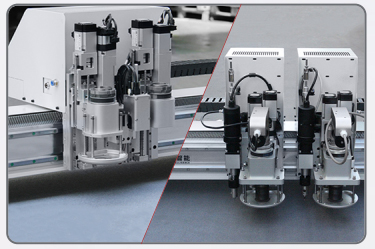

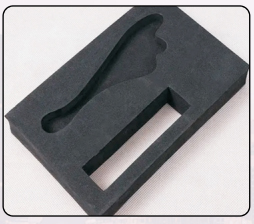

► Universal knife holder design, allowing for quick replacement with pneumatic knives, creasing knives, bevel knives, half-cut knives, round knives, and other tools, enabling high-speed completion of various processes such as half-cutting, full-cutting, creasing, slotting, beveling, and contour recognition cutting. (Dual knife holders and dual knife interchanging can be configured as needed.)

► The LIKA software system can be paired with models for small-batch sampling and mass production, enabling rapid cutting for both large and small orders (no die-cutting required), quickly responding to customer needs.

► The entire machine uses AC servo drive, with XY axes configured with precision planetary gear reducers, providing strong power and rapid response. The transmission uses ground rack and linear square guide rails. A high-strength aviation cast aluminum beam is used, with gantry precision milling, ensuring stable and reliable operation at high speeds and precise cutting.

► Adopts a replaceable head design concept. The tool head is not fixedly welded, allowing for easy addition or replacement of cutting heads according to actual work needs and business expansion.Details

Dual Knife Holder/Dual Head Interchanging (Optional)

Universal multi-knife holder design, allowing for configuration of various tools according to material.Gantry Beam Transmission

High-strength aviation cast aluminum beam with gantry precision milling. XY axis uses ground rack and guide rail transmission.Honeycomb Aviation Aluminum Platform + Custom Felt

The excellent honeycomb table top, paired with a custom, highly breathable felt for the table, firmly secures the material.No Software Restrictions

Can connect to DXF files and major CAD system files, and can be equipped with multiple systems to meet the cutting needs of various materials.Equipment Parameters

Model 6090/1210/1216/1416/2513/2516 Intelligent Cutting Machine (Customizable Size)

Standard Tool Oscillating knife/Pneumatic knife + Creasing knife (optional)

Standard Configuration Vacuum Adsorption

Transmission Motor Servo Motor

Transmision Guide Rail High-precision guide rail transmission + precision ground rack

Adsorption Platform All-aluminum honeycomb adsorption fixing platform

Maximum Speed 1200mm/s

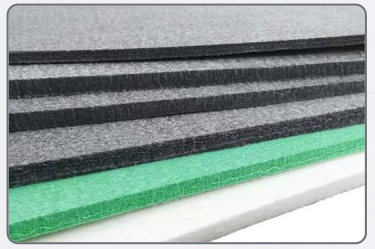

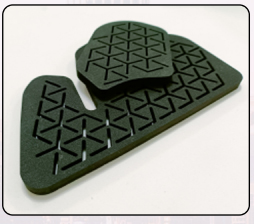

Cutting Material Corrugated paper, hollow board, gray cardboard, pearl cotton, EVA, and other flexible materials in multiple industries

Equipment Voltage AC220V±10%50Hz

Fan Power 7.5KW (default configuration can be changed)

Cutting Area 2400×1300(mm)

Overall Dimensions 3370mm×2100mm×1250mm

Industry Applications

Corrugated Paper Hollow Board Gray Cardboard Pearl Cotton EVA EVA

preceding line: 2516 black and white mutual transfer single head

Product Inquiry

* Note: Please leave your contact information, our professionals will contact you as soon as possible!