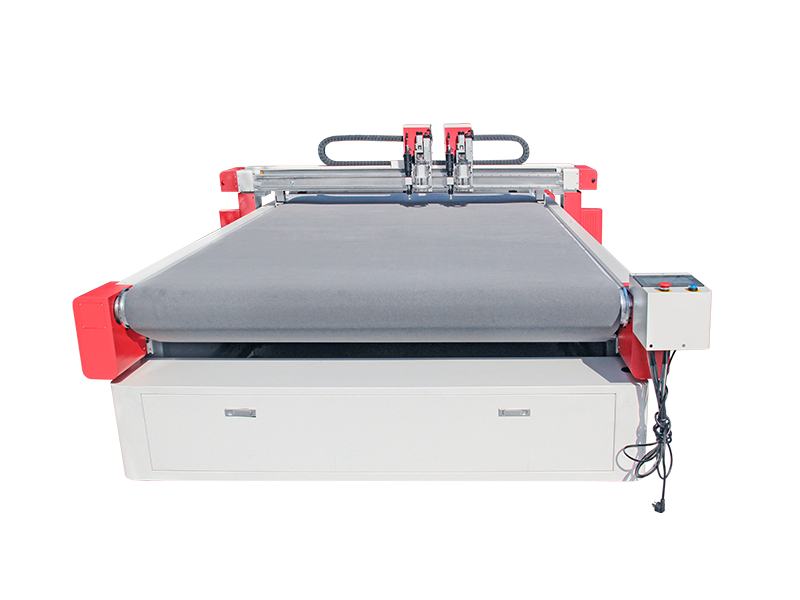

2516 red and white mutual shift double head

Share

2516 red and white mutual shift double head

Still considering? If you are interested, you canContact us!

Keywords:

- Product Description

-

Product Features

► Felt conveyor belt type rolling material workbench, equipped with a honeycomb aluminum adsorption platform, and with a rear loading rack, continuous processing of rolls can be realized. It can be connected to various material receiving or post-processing platforms, adapting to most high-speed processing scenarios and material requirements.

► The whole machine adopts AC servo drive, XY axis is configured with precision planetary gear reducer, powerful and quick response. The transmission adopts ground rack and linear square guide rail. High-strength aviation cast aluminum beam is used, gantry milling processing, stable and reliable at high-speed operation, precise cutting.

► Universal knife seat design, can be quickly replaced with pneumatic knife, creasing knife, bevel knife, half-cut knife, circular knife and other various tools to complete various processes such as half-cutting, full-cutting, creasing, slotting, beveling, contour recognition cutting at high speed.

► Industrial 5-8 axis edge detection control system, network cable connection, quick deployment. Supports automatic typesetting. High-resolution CCD camera positioning, intelligent extraction of cutting contours, realizing fast cutting.

Details Display

Multiple Knife Seats

Different tools can be installed, during multi-process/procedure processing

Can be processed alternately to meet different process needs.Gantry Beam Transmission

High-strength aviation cast aluminum beam with gantry milling processing.

High-precision guide rail transmission + customized belt transmissionAutomatic Feeding

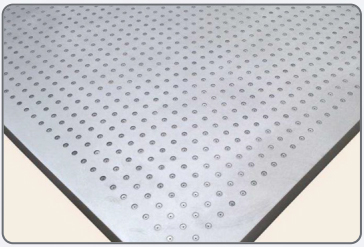

Realize continuous cutting of rolls, no need for time-consuming and laborious manual loadingPlatform

Aviation aluminum honeycomb adsorption platform, adsorption can be controlled in zonesEquipment Parameters

Model 2513/2516 Advertising Irregular Cutting Machine (More sizes can be customized)

Standard Tool Double knife seat + small vision (optional)

Standard Configuration CCD vision + vacuum adsorption

Transmission Motor Servo Motor

Transmision Guide Rail High-precision guide rail transmission + belt transmission

Adsorption Platform Full aluminum honeycomb adsorption fixing platform

Maximum Speed 1200mm/s

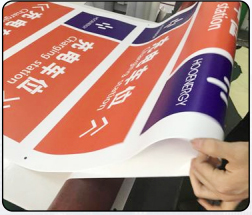

Cutting Material Car stickers, back glue, KT board, self-adhesive, photos, light box cloth, printed cartons, etc.

Equipment Voltage AC220V±10%50Hz

Fan Power 7.5KW (default configuration can be changed)

Cutting Area 2500×1300/2500×1600(mm)

overall Dimensions 3370×2100×1250/3370×2300×1250(mm)

Industry Applications

Car Stickers Back Glue KT Board Self-adhesive Photos Light Box Cloth

Product Inquiry

* Note: Please leave your contact information, our professionals will contact you as soon as possible!