2516 black and white double-beam feeding three-head

Share

2516 black and white double-beam feeding three-head

Still considering? If you are interested, you canContact us!

Keywords:

- Product Description

-

Product Features

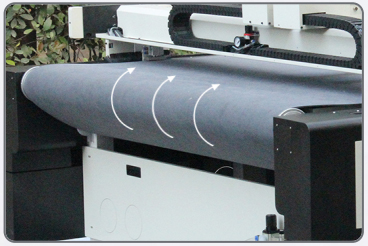

► Felt conveyor belt rolling table, equipped with a honeycomb aluminum adsorption platform. Combined with a rear loading rack, it enables continuous processing of rolls. It can be connected to various material receiving or downstream processing platforms, adapting to most high-speed processing scenarios and material requirements.

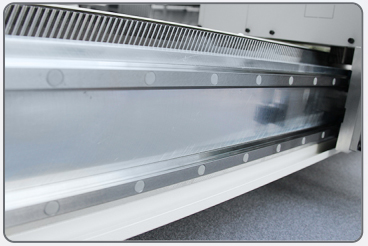

► The whole machine adopts AC servo drive, with XY axis configured with precision planetary gear reducer, powerful and quick response. The transmission uses ground rack and square linear guide rail. It adopts high-strength aviation cast aluminum beam, gantry milling, stable and reliable at high-speed operation, precise cutting.

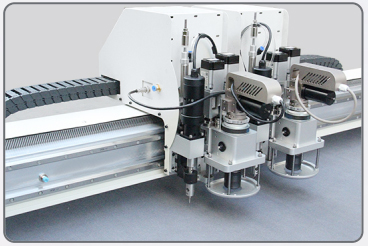

► Dual-knife synchronous cutting, double the efficiency; it can achieve multi-layer cutting and punching according to material characteristics, completing the regular material cutting process in one go, meeting the production goals of small batches, multiple orders, and multiple styles.

► The LIKA software system can control and manage the cutting software, adjusting parameters such as cutting size, style, and quantity according to needs. It also performs data management and analysis to shorten cutting time, achieve production flexibility, and improve production quality and efficiency.

Details

Dual Knife Interchangeable

Synchronous cutting of the same component, doubling production efficiency. Some sub-models

Equipped with milling tools, supporting flexible cutting while also allowing for engraving on hard materials.Gantry Guide Rail Transmission

Gantry precision-milled high-strength aviation cast aluminum beam. X/Y axis grinding-grade rack and pinion guide rail transmissionAutomatic Feeding

Achieves continuous cutting of rolls, eliminating the need for time-consuming and laborious manual loadingPlatform

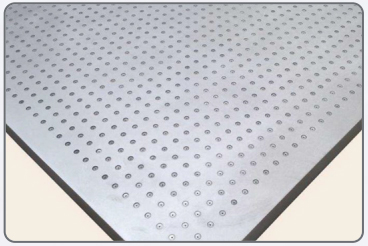

Honeycomb aviation aluminum adsorption platform, with zonal adsorption controlEquipment Parameters

Model LK series 1216/1616/2516 dual-knife interchangeable cutting machine

Standard Tool Dual knife holder + dual punching

Standard Configuration Infrared positioning + vacuum adsorption

Transmission Motor Servo motor

Transmision Guide Rail High-precision guide rail transmission + ground rack

Adsorption Platform Honeycomb aviation aluminum adsorption fixing platform

Maximum Speed 1200mm/s

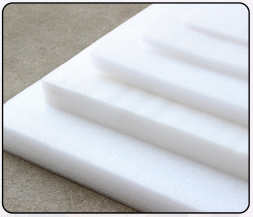

Cutting Material Leather, cloth, sponge, silicone, rubber, XPE, EVA, etc.

Equipment Voltage AC220V±10%50Hz

Fan Power 7.5KW (default configuration can be changed)

Cutting Area 1200×1600/1600×1600/2500×1600(mm)

overall Dimensions 2100×2270×1250/2500×2270×1250/3370×2270×1250(mm)

Industry Applications

EVA Carton EPE Foam Fabric Fabric Leather

preceding line: Custom-made machine with freight of 6080

Product Inquiry

* Note: Please leave your contact information, our professionals will contact you as soon as possible!