2516 double-beam feeding double-head

Share

2516 double-beam feeding double-head

Still considering? If you are interested, you canContact us!

Keywords:

- Product Description

-

Product Features

► Felt conveyor belt-type rolling material workbench, equipped with a honeycomb aluminum adsorption platform. Combined with a rear loading rack, it can achieve continuous processing of rolls. It can be connected to various material receiving or post-processing platforms, adapting to most high-speed processing scenarios and material requirements.

► The whole machine adopts AC servo drive, and the XY axis is equipped with a precision planetary gear reducer, which is powerful and responsive. The transmission uses ground rack and linear square guide rails. High-strength aviation cast aluminum beams are used, with gantry precision milling, ensuring stable and reliable operation at high speeds and precise cutting.

► Universal knife holder design, allowing for quick replacement with pneumatic knives, creasing knives, bevel knives, half-cut knives, circular knives, and other tools, enabling high-speed completion of various processes such as half-cutting, full-cutting, creasing, slotting, beveling, and contour recognition cutting.

► Industrial 5-8 axis edge detection control system, network cable connection, quick deployment. Supports automatic typesetting. High-resolution CCD camera positioning, intelligent extraction of cutting contours, enabling fast cutting.

Details

Multiple Knife Holders

Different tools can be installed for processing multiple processes/procedures.

Alternating processing can meet different process needs.Gantry Beam Transmission

High-strength aviation cast aluminum gantry precision-milled beam.

High-precision guide rail transmission + custom belt transmissionAutomatic Feeding

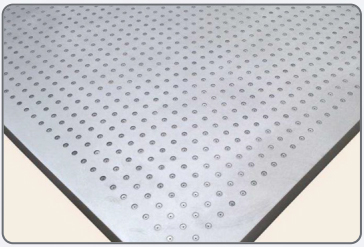

Achieves continuous cutting of rolls, eliminating the need for time-consuming manual loading.Platform

Honeycomb aluminum adsorption platform, with zonal adsorption control.Equipment Parameters

Model 2513/2516 Advertising Irregular Cutting Machine (More sizes can be customized)

Standard Tool Dual knife holder + small vision (optional)

Standard Configuration CCD vision + vacuum adsorption

Transmission Motor Servo motor

Transmission Guide Rail High-precision guide rail transmission + belt transmission

Adsorption Platform Full aluminum honeycomb adsorption fixing platform

Maximum Speed 1200mm/s

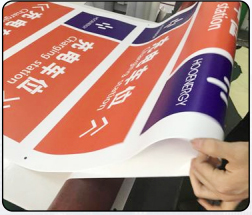

Cutting Materials Car stickers, back glue, KT board, self-adhesive stickers, photo prints, light box cloth, printed cartons, etc.

Equipment Voltage AC220V±10%50Hz

Fan Power 7.5KW (default configuration can be changed)

Cutting Area 2500×1300/2500×1600(mm)

Overall Dimensions 3370×2100×1250/3370×2300×1250(mm)

Industry Applications

Car Stickers Back Glue KT Board Self-adhesive Stickers Photo Prints Light Box Cloth

preceding line: 1210 sheet material sample machine single head

Next: NO!

Product Inquiry

* Note: Please leave your contact information, our professionals will contact you as soon as possible!